Thread selection is one of the most underestimated aspects of pneumatic system design.

In practice, many air leakage problems, unstable connections, and repeated maintenance issues are not caused by poor-quality components, but by incorrect thread selection or mismatched thread standards.

PT, G, NPT, and Metric (M) threads are the most commonly used thread types in pneumatic fittings worldwide. While these threads may look similar at first glance, they differ significantly in geometry, sealing principle, applicable standards, and long-term performance.

This article provides a practical, engineering-focused explanation of pneumatic fitting thread types and explains how to choose the right one for your application.

Why Do Different Thread Types Exist in Pneumatic Systems?

Pneumatic technology did not evolve under a single global standard. Instead, it developed independently across different regions, each with its own industrial background, manufacturing capability, and engineering priorities.

Regional Standards and Industrial Evolution

In Europe, Asia, and North America, piping and fitting standards were established long before global standardization became common. Each region optimized thread designs based on local needs, available materials, and machining practices. Over time, these designs became deeply embedded in equipment specifications and industrial supply chains.

As a result, multiple thread standards coexist today, not because of poor coordination, but because they were proven to work reliably within their original contexts.

A Shared Engineering Objective

Despite their differences, all pneumatic fitting threads are designed to achieve the same goal: To create a mechanically stable, airtight connection between components under pressure

The existence of multiple thread types reflects different engineering approaches to achieving sealing reliability, rather than unnecessary complexity.

Why Pneumatic Systems Cannot Use a Single Universal Thread

From an engineering perspective, pneumatic connections must balance several competing requirements that cannot be optimized by a single design.

Engineering Trade-Offs in Thread Design

Pneumatic fittings must simultaneously address:

-

Reliable sealing under pressure

-

Ease of installation and maintenance

-

Resistance to vibration and repeated assembly

-

Compatibility with existing equipment

Some thread designs prioritize self-sealing through mechanical interference, while others separate the functions of fastening and sealing. Because these approaches solve different problems, no single thread type can serve all applications effectively.

Two Fundamental Categories of Pneumatic Threads

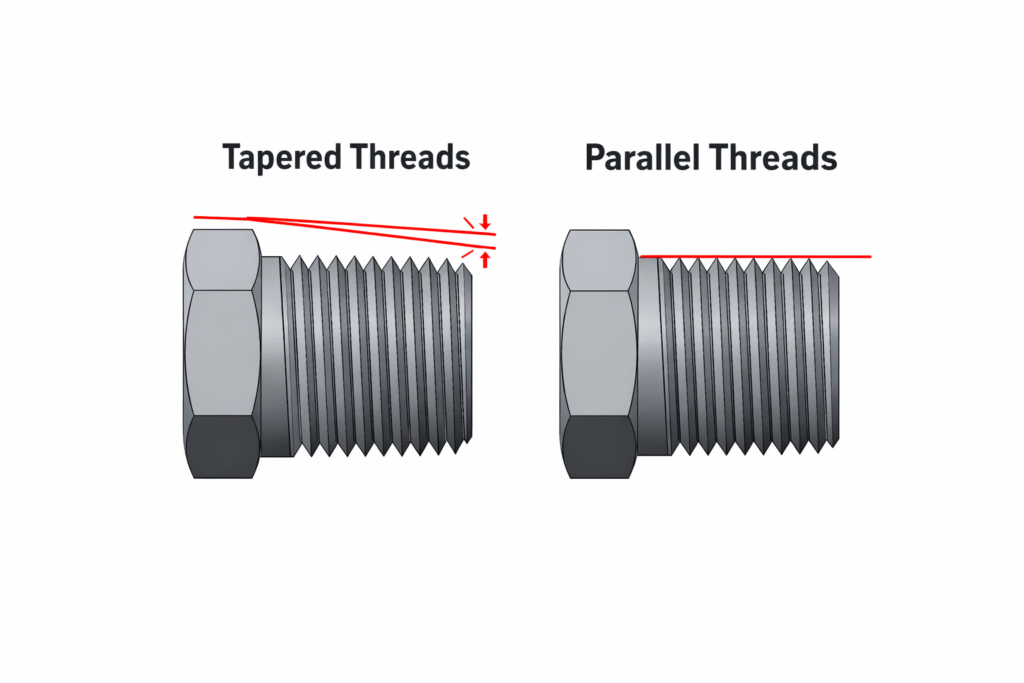

In practical system design, pneumatic threads fall into two main categories:

-

Tapered threads, which seal through thread interference

-

Parallel threads, which rely on an external sealing element such as an O-ring or washer

Understanding this distinction is far more important than memorizing specific standards.

Overview of Common Pneumatic Thread Types

Before examining each thread type in detail, it is helpful to understand their basic differences.

| Thread Type | Thread Form | Sealing Principle | Typical Regions |

|---|---|---|---|

| PT | Tapered | Thread interference | Asia / Japan |

| NPT | Tapered | Thread interference | North America |

| G (BSPP) | Parallel | O-ring or washer | Europe / International |

| Metric (M) | Parallel | O-ring or face seal | Metric-based systems |

This overview provides general guidance, but actual thread selection should always consider equipment design and application conditions.

PT Thread (BSPT – British Standard Pipe Taper)

PT threads are widely used in traditional pneumatic systems, particularly in Asian markets. They belong to the family of tapered pipe threads, meaning the thread diameter gradually decreases along the axis.

How PT Threads Seal

Because of their tapered geometry, PT threads seal through mechanical interference between the male and female threads. As the fitting is tightened, the threads compress against each other, creating an airtight seal. In most installations, PTFE tape or liquid thread sealant is applied to fill microscopic gaps and enhance sealing performance.

Practical Advantages and Limitations

PT threads are simple, widely available, and familiar to many technicians. However, their sealing performance depends heavily on installation technique. Under-tightening can result in leakage, while over-tightening may damage threads or crack valve bodies, especially in aluminum components.

Repeated assembly and disassembly gradually reduce sealing reliability, making PT threads better suited for relatively stable installations where frequent maintenance is not required.

NPT Thread (National Pipe Taper)

NPT threads are the most common tapered thread standard in North America. While they appear similar to PT threads, they follow a different standard and use a different thread angle.

Structural Characteristics of NPT Threads

Like PT threads, NPT threads rely on taper-induced interference for sealing. However, the thread profile and angle differ, making them incompatible with PT threads despite their visual similarity.

Common Installation Mistakes

A frequent and costly mistake in pneumatic systems is attempting to mix PT and NPT threads. Even if the fitting can be screwed in, the mismatched thread geometry often leads to hidden leakage or premature failure.

For this reason, NPT threads should only be used in systems specifically designed for the NPT standard, particularly in equipment intended for the U.S. market.

G Thread (BSPP – British Standard Pipe Parallel)

G threads represent a fundamentally different sealing philosophy. They use a parallel (straight) thread, meaning the thread diameter remains constant along the entire length.

Separation of Fastening and Sealing

Unlike tapered threads, G threads do not provide sealing through the threads themselves. Instead, sealing is achieved by compressing an O-ring or sealing washer against a flat surface when the fitting is tightened.

This separation of mechanical fastening and sealing makes performance more predictable and repeatable, regardless of installation torque.

Engineering Benefits in Modern Systems

Because sealing does not rely on thread deformation, G threads tolerate repeated assembly much better than tapered threads. This makes them especially suitable for industrial automation systems, valve manifolds, and modular pneumatic assemblies, where components are frequently serviced or reconfigured.

Metric Thread (M Thread)

Metric threads follow the ISO metric system and are increasingly common in modern pneumatic equipment. Like G threads, they use a parallel thread form and rely on an external sealing element.

Compatibility and Standardization

Metric threads integrate seamlessly with metric-based mechanical designs, simplifying standardization across equipment platforms. Sealing is typically achieved through an O-ring or face seal, offering consistent performance and reduced risk of leakage.

Growing Use in Modern Pneumatics

As pneumatic systems become more compact and standardized, metric threads are gaining popularity, particularly in new-generation automation equipment and precision applications.

How to Choose the Right Pneumatic Thread Type

Selecting the correct thread type does not require memorizing standards if basic engineering principles are followed.

Practical Selection Guidelines

-

Always match the original port thread specified by the equipment manufacturer

-

Use parallel threads (G or M) where frequent maintenance is expected

-

Avoid tapered threads in applications where sealants are restricted

-

Ensure compliance with destination market standards for export equipment

Engineering Perspective

Tapered threads rely more on installation technique.

Parallel threads rely more on proper sealing design.

Understanding this distinction helps prevent many long-term reliability issues.

Frequently Asked Questions About Pneumatic Threads

Can PT and NPT threads be used together?

No. They follow different standards and should never be mixed, even if they appear compatible.

Can G threads seal without an O-ring?

No. G threads are not self-sealing and always require a sealing element.

Are metric threads better than G threads?

Not inherently. The correct choice depends on system design, standardization requirements, and application conditions.

What causes most pneumatic thread leakage?

In most cases, leakage is caused by incorrect thread selection or improper installation, rather than component quality.

Conclusion: Why Thread Selection Matters

PT, G, NPT, and Metric threads are not interchangeable alternatives. They are engineering solutions developed for different standards, regions, and application requirements.

Correct thread selection helps to:

-

Reduce air leakage

-

Improve system reliability

-

Lower long-term maintenance costs

In pneumatic systems, thread selection is a design decision with long-term consequences, not a minor detail.

If you are looking for pneumatic fittings compatible with different thread standards—including PT, G, NPT, and Metric threads—you can explore our full range of pneumatic connectors designed for industrial applications.